EPR INSTALLATION

INCREASED FLEXIBILITY

REDUCED EXTERNAL BENDING FORCES

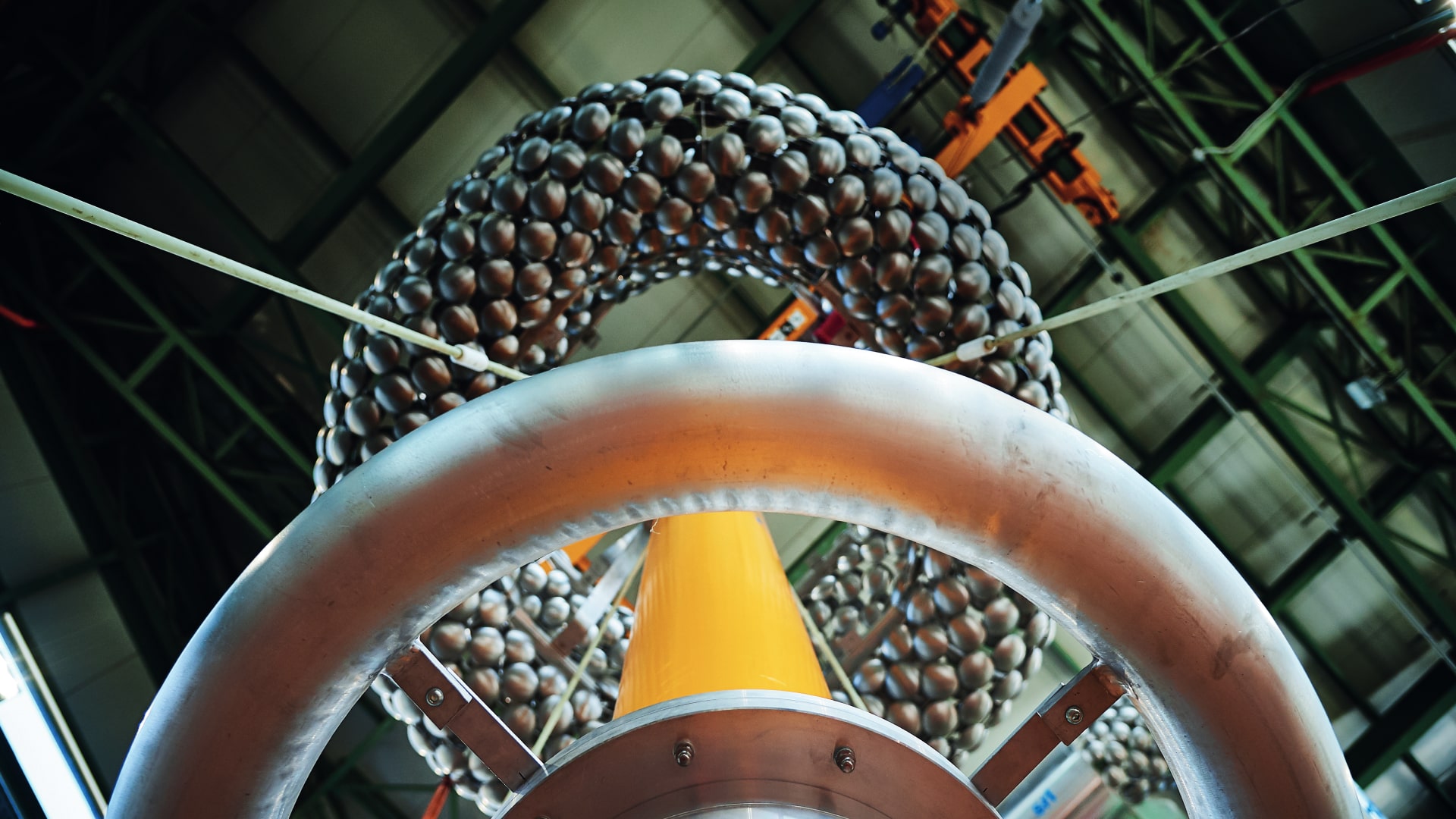

The first stage in using a cable is obviously installation, and a primary reason for the move from paper to elastomeric insulated cables is ease of installation and handling.

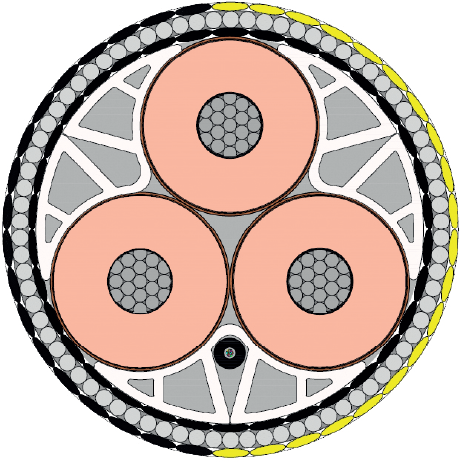

The use of an appropriate elastomeric insulation removes the necessity for a metal sheath, thus considerably simplifying cable installation.

EPR has the advantage of an elastic modulus lower than XLPE, which makes it easier to install, particularly if the operation has to be undertaken in restricted spaces (such as underground passages, ducts, or offshore structures), or into internal switchgear. Increased flexibility of the cable core could be a significant advantage to the jointing and termination operations where careful alignment is necessary in a limited space.

The reduced external bending forces in an EPR insulated cable also reduce the internal stresses between insulation and screen which, in extreme cases, could cause problems with the formation of voids.

Joints and terminations are generally the same as those used for installation of XLPE cables, hence minimising the need for jointer training.

Bending stiffness at slide speed of 10 mm/sec for different bending radii