The world’s densest fibre cable with a proven fifty-year+ lifespan

New and rigorous long-term ageing testing on the Sirocco family of cables, proving expected lifetime of more than 50 years, allowing operators to calculate the life cycle analysis of their networks over an extended period. Ian Griffiths, Global Digital Solutions R&D VP at Prysmian, explains…

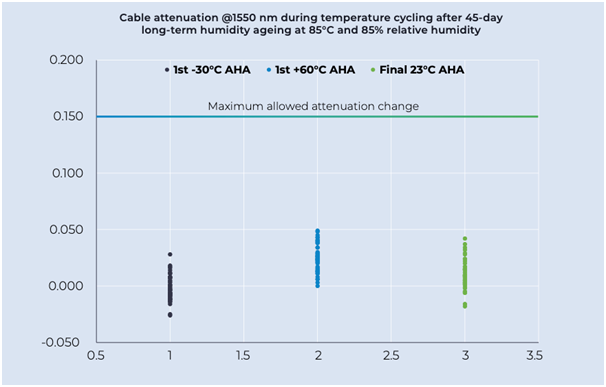

Prysmian’s Sirocco HD and Extreme cables are already well known as highly sustainable and extremely efficient solutions. Due to their extra-compact size and extreme fibre density, they’re easily deployable, make the most of limited duct space, require fewer raw materials and reduce transportation costs. Following optimisation of the optical fibre and materials, and rigorous testing, Sirocco cables are shown to have an expected lifetime of more than 50 years, without any compromise on performance during that time.