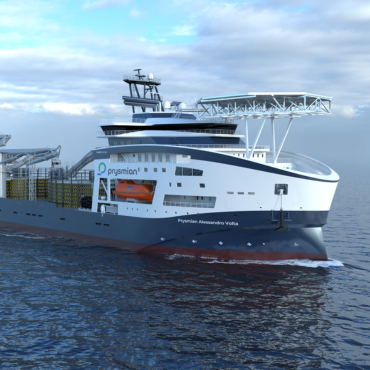

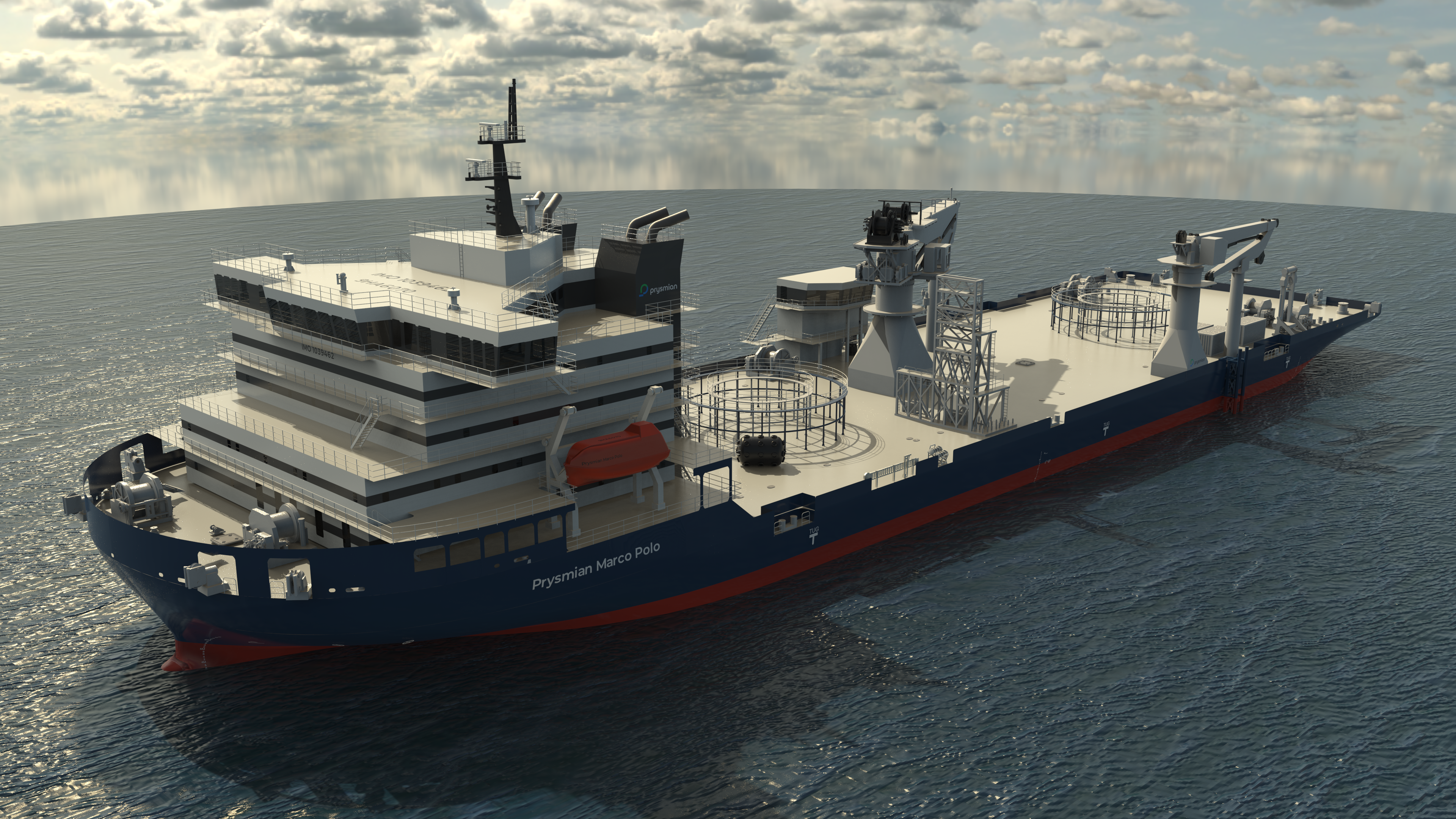

OVERVIEW

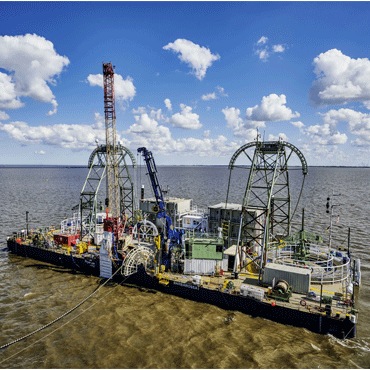

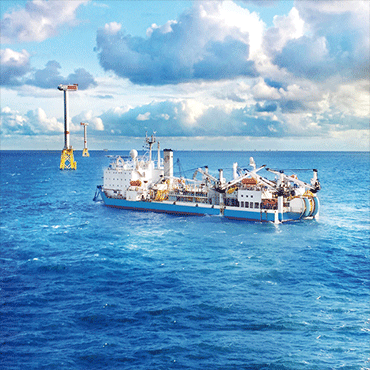

Installation capabilities

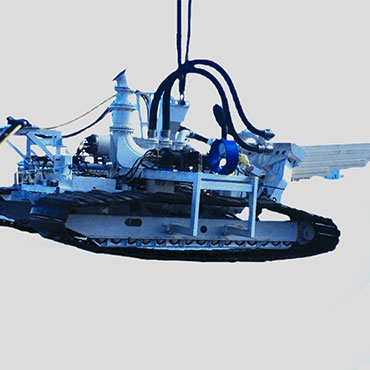

With a fleet of eight cable laying vessels, Prysmian has the largest state-of-the-art fleet in the industry. We make the best use of the available resources to ensure project efficiency and safety at all times. From shallow water to deep water up to 3,000 m, from soft soils to hard soils, from single cable to bundled cables, we have the experience and assets to provide complete solutions across all manner of cable installations.